Ultrasonic Machining Module

Increased Productivity

- The ULTRASONIC technology from FEELER enables the economical machining of complex workpiece geometries in demanding advanced materials such as ceramics, glass, corundum, tungsten carbide or even composite materials.

- Based on the advanced development of the ultrasonic technology according to the requirement of the market, FEELER ultrasonic machine can provide high efficiency and high-quality machining of complex materials such as precision ceramics, quartz glass, alumina, tungsten steel, and super alloys or even composite materials.

- The kinematic overlapping of the tool rotation with an additional oscillation effects a reduction of the process forces by up to 40% in comparison to conventional machining. Depending on the work-piece requirements, this allows higher feed rate, provides longer tool life and significantly surface finishing of up to Ra < 0.1 μm.

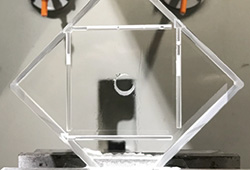

Ultrasonic Toolholder

- Plug & Play Transmitter

Compatible for variable CNC machine tool - Non-contact Ultrasonic

Optimised inductive transmission - Reinforced Actuator

To achieve high stiffness - Ultrasonic vibration amplitude

0 - 15 μm(Depanding on tool settings) - Tools

With undefined and defined cutting edge (Diamond grinding rod, milling tool and drilling tool)

Design for Advanced Materials

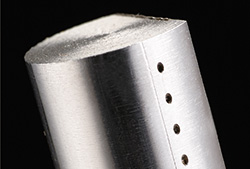

TUNGSTEN STEEL

- Without polishing, near mirror finish surface (Ra<0.1μm)

- Processing efficiency increases 4 times, compared to EDM

- Same processing method, efficiency increases 1.6 times

- Reducing the processing procedures

- Longer tool life by 4 times

INCONEL

- Efficiency enhanced by 30% compared to non-ultrasonic

- Prolongs tool life

SAPPHIRE

- Processing efficiency increases 4 times, compared to non-ultrasonic

- Effectively reduce the workpiece chippingand surface micro-cracks

QUARTZ

- Better quality, compared to non-ultrasonic

- Efficiency enhanced by 800% compared to non-ultrasonic

AISI 304

- Processing efficiency increases 3 times

- Significant quality improvement reducing entry distortions decreasing hole roughness

SILICON CARBIDE

- Break the limitation of non-ultrasonic machining, increase the removal rate up to 5 times

- Better quality, reducing surface roughness by 30%

ZIRCONIUM DIOXIDE

- Better quality, compared to non-ultrasonic

- Processing time reduced by half

- Longer tool life by 3 times

HONEYCOMB STRUCTURE

- Not only meeting the customer inclined surface qualities, but increases the roughing efficiency by 4 times

- At the same quality standard, the finishing efficiency can be increased by 2 times