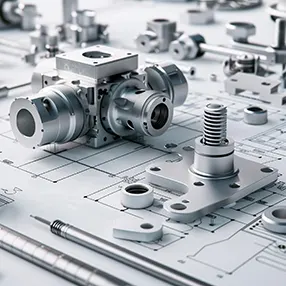

Customers demand stable production, reliable quality, and partners they can trust for the long term.

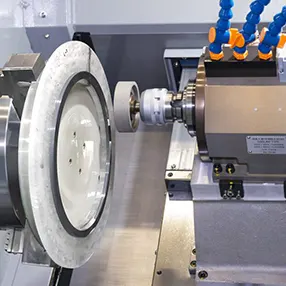

At FEELER, we understand that every machining process affects delivery schedules, costs, and brand reputation. Leveraging high-rigidity structures, precision control, and smart manufacturing, we provide flexible solutions for diverse materials and workpieces, helping clients increase productivity, reduce risk, and shorten development-to-production cycles.

From automotive and aerospace to semiconductors, medical, energy, and mold manufacturing, FEELER combines proven technology with comprehensive support to streamline production processes, ensure consistent output, and helping customers maintain a competitive edge in the market.

As the automotive sector rapidly evolves toward electrification, smart manufacturing, and lightweight design, precision machining technology becomes increasingly critical.

FEELER delivers high-rigidity, highly stable machine tools to meet the diverse requirements of vehicle body structures, powertrains, and chassis components. Our solutions balance productivity and quality, empowering customers to overcome the challenges of modern automotive manufacturing with superior machining capabilities.

Aerospace components are typically made from high-strength and composite materials with complex geometries and extremely tight tolerances. FEELER leverages advanced machining technologies and highly stable machine tools to achieve high precision, efficiency, and reliability required for critical manufacturing processes.

From large structural parts to engine components and landing gear assemblies, FEELER provides high-rigidity, highly stable machining solutions that meet aerospace-grade manufacturing standards, ensuring consistent quality and performance for the most demanding applications.

Semiconductor technology lies at the core of modern electronic products, powering applications in mobile communications, computing devices, automotive electronics, and medical technology, and shaping global industrial development. With the rise of AI, electric vehicles, and high-speed computing, the demands for chip performance and process precision continue to increase. These components are manufactured using diverse materials, including aluminum alloys, stainless steel, quartz glass, and carbon fiber composites.

FEELER combines precision, stable machine tools with extensive manufacturing expertise to help clients produce highly complex components accurately. This ensures both equipment quality and production efficiency, driving continuous innovation in high-tech manufacturing.

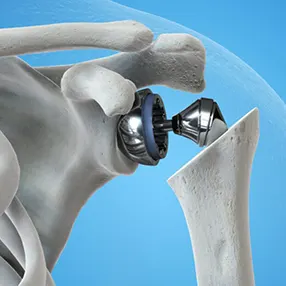

The medical industry demands the highest standards of safety and precision. From artificial joints and dental implants to advanced surgical instruments, every component requires extreme accuracy and consistent quality.

With years of precision machining experience, complex components can be manufactured from titanium, stainless steel, and polymer materials. Clients are supported in meeting strict quality regulations, producing safer and more reliable medical products, and ensuring that every medical component fully complies with industry standards.

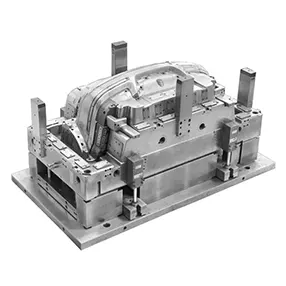

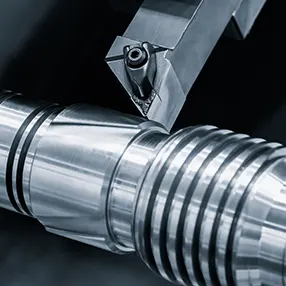

Mold and general manufacturing form the foundation of modern industry, covering automotive components, appliance housings, precision mechanisms, and various consumer products. High-quality molds not only determine product appearance and precision but also impact overall production efficiency and cost control.

With FEELER’s high-rigidity machine structures and stable cutting performance, complex components of varying materials and sizes can be processed efficiently. Whether producing automotive molds, appliance housings, or general components, every operation is carried out with stability, efficiency, and precision. Intelligent process control and reliable machining performance help clients achieve high productivity and accuracy, enhancing overall manufacturing competitiveness.

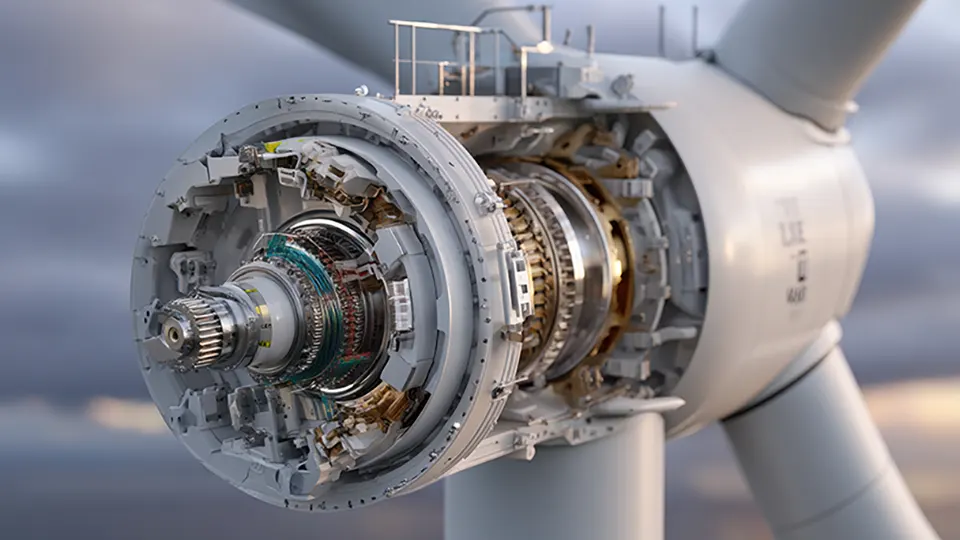

Energy technology is moving toward diversification and sustainability, spanning wind power, solar energy, and petrochemical industries. All types of equipment place high demands on the strength and durability of critical components.

With FEELER’s high-rigidity machine structures and stable machining performance, complete solutions are provided for structural components and high-strength materials. Whether producing turbine components, compression systems, or energy equipment parts, our machines maintain outstanding precision and stability during long operational periods, helping clients enhance productivity and drive the energy industry toward a more efficient and sustainable future.

Solar Energy

Petrochemical

Nuclear Energy

Wind Energy