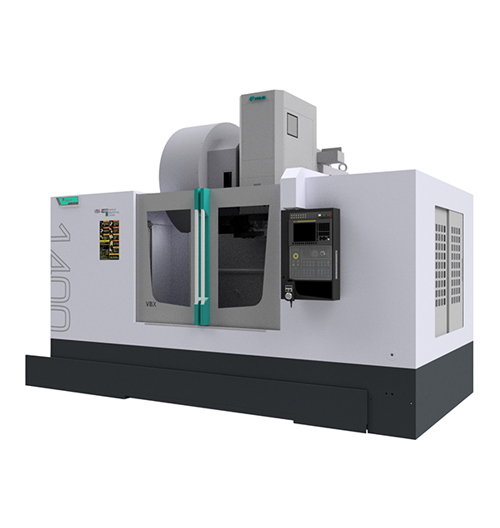

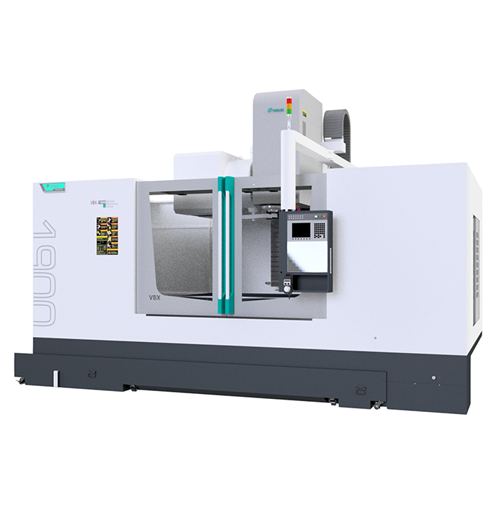

Vertical Machining Center

The VBX Series box way machining centers are engineered for heavy duty cutting and general part production, delivering outstanding rigidity and stability. All three axes feature extra-wide box way construction, which enhances cutting performance and reduces cycle time. The machine body is constructed from Meehanite cast iron, ensuring long-term durability and dimensional stability under continuous operation.

Each axis guideway is heat treated, precision ground, and coated with Turcite B, minimizing wear and maintaining long-lasting accuracy. The feed screw system is integrated with an automatic lubrication system, extending bearing life and ensuring smooth operation. Finite element method (FEM) structural analysis and dynamic simulation were performed during the design stage to optimize rigidity, precision, and reliability. Even under heavy load conditions, the VBX Series maintains stable machining performance, offering manufacturers a powerful and efficient solution that meets the dual demands of accuracy and productivity.

.png)

| Item | Unit | VBX-1100 (#40/50) |

VBX-1300 (#40/50) |

VBX-1400 (#40/50) |

VBX-1650 (#40/50) |

VBX-1900 (#50) |

VBX-2200 (#40/50) |

|---|---|---|---|---|---|---|---|

| X Axis Travel | mm | 1100 | 1300 | 1400 | 1650 | 1900 | 2200 |

| Y Axis Travel | mm | 610 | 610 | 800 | 800 | 860 | 960 |

| Z Axis Travel | mm | 600 | 600 | 700 | 700 | 800 | 800 |

| Table Dimensions | mm | 1300x600 | 1500x600 | 1650x800 | 1900x800 | 2100x860 | 2400x960 |

| Max. Loading Weight | kg | 1300 | 1300 | 1500 | 1800 | 2200 | 2700 |

| Spindle Speed | rpm | 10000/4000 | 10000/4000 | 10000/4000 | 10000/4000 | 4000 | 1000/4000 |

| Spindle Taper | - | 7/24 Taper No.40/No.50 | 7/24 Taper No.40/No.50 | 7/24 Taper No.40/No.50 | 7/24 Taper No.40/No.50 | 7/24 Taper No.50 | 7/24 Taper No.40/No.50 |

| X Axis Rapid Traverse | m/min | 24 | 24 | 20 | 20 | 15 | 15 |

| Y Axis Rapid Traverse | m/min | 24 | 24 | 20 | 20 | 15 | 15 |

| Z Axis Rapid Traverse | m/min | 24 | 24 | 18 | 18 | 12 | 12 |

| No. of Tools | T | 24 | 24 | 24 | 24 | 32 | 32 |