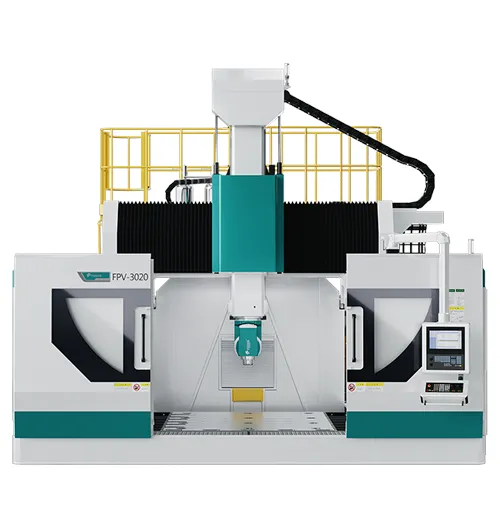

Vertical Machining Center

The RG Series is designed for high-speed machining of large aluminum components, making it the preferred solution for new energy vehicle manufacturing. It meets the demanding requirements of complex, multi-angle, and high-precision machining, while its lightweight structural design enhances both movement speed and machining efficiency.

The spindle head utilizes a dual accumulator and nitrogen energy storage system for precise balance control. Independent cooling systems for the spindle and secondary head maintain optimal temperature stability and reduce deformation from thermal interference.

The X-axis features a direct-drive reducer, providing strong torque output, while Y and Z axes adpot direct transmission for maximum rigidity. Equipped with a high-precision five-axis head, the machine performs 3+2 simultaneous machining on complex surfaces. Rapid traverse speeds of 40 / 40 / 36 m/min (X / Y / Z) ensure outstanding productivity

| Item | Unit | RG-3020 | RG-6020 | RG-9020 | RG-12020 |

|---|---|---|---|---|---|

| X Axis Travel | mm | 3000 | 6000 | 9000 | 12000 |

| Y Axis Travel | mm | 2000 | |||

| Z Axis Travel | mm | 1200 | |||

| Table Dimensions | mm | 2000x3000 | 2000x6000 | 2000x9000 | 2000x12000 |

| Max. Loading Weight | kg | 5000 | |||

| Spindle Speed | rpm | 20000 | |||

| Spindle Taper | - | HSK-A63 | |||

| X Axis Rapid Traverse | m/min | 40 | |||

| Y Axis Rapid Traverse | m/min | 40 | |||

| Z Axis Rapid Traverse | m/min | 36 | |||

| No. of Tools | T | 40 | |||