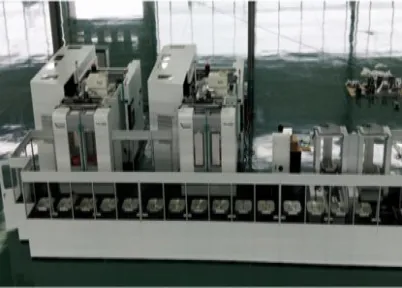

In modern manufacturing, automation is no longer a single fixed solution. It functions as a scalable strategy that adapts to production volume, product mix, and machining characteristics.

For high-mix, low-volume workpieces requiring rapid changeovers, or for high-volume, long-run batch machining, technologies such as automated loading/unloading, quick-change tooling, and intelligent scheduling systems significantly shorten setup time, increase flexibility, and improve overall equipment utilization.

Whether deployed a standalone machine or integrated into a complete system, each configuration can be expanded into a more adaptable solution tailored to the customers operations.

• Fast throughput suitable for high-mix, low-volume production

• Rigid construction with excellent load capacity

• Compatible with various automation modules and workholding systems

• Ideal for lightweight workpieces with high-speed movement

• Accurate positioning ensures strong production efficiency

• Upper–lower clamping enables rapid material changeover

• Designed for high-mix, low-volume machining environments

• Supports mixed-line production for different processes or different workpieces

• Enables coordinated part production and reduces setup time

• Modular system architecture for easy expansion

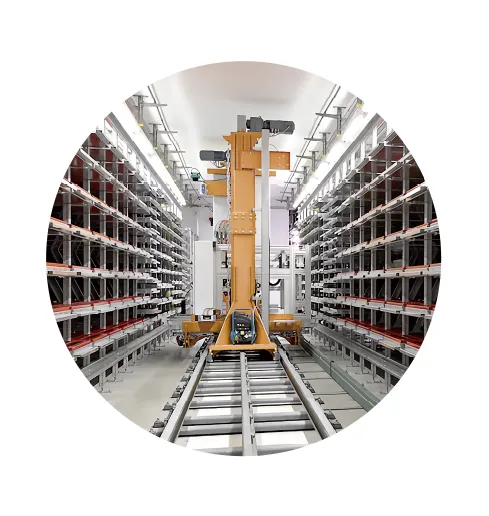

• Real-time monitoring of machine status, line performance, and tool life

• Key information displayed through mobile apps and digital dashboards

• Minimizes defects and ensures consistent yield

• Centralized platform integration simplifies operation and maintenance

Every industry faces unique challenges. Through tailored automation solutions, we help clients increase productivity, maintain consistent quality, and reduce operational costs.

Each Solutions are customized to the user’s specific requirements, delivering optimal equipment configurations and integrated automation that generate tangible results.

Efficient automation requires more than just core machines. Supporting peripheral equipment can be flexibly integrated to optimize production lines and achieve a complete, high-efficiency workflow.

FEELER developed the FAIR Controller to ensure stable operation and maximize productivity in automated production lines. It provides real-time monitoring, converts production data into actionable insights, supports flexible work order management, and includes preventive maintenance functions to maintain smooth operation and improve overall efficiency.