Amid rapid industrial transformation, factories are moving beyond basic automation toward fully integrated smart solutions. By connecting equipment, centralizing data, and leveraging advanced analytics, we build intelligent factories that respond in real time, predict production outcomes, and operate with high efficiency.

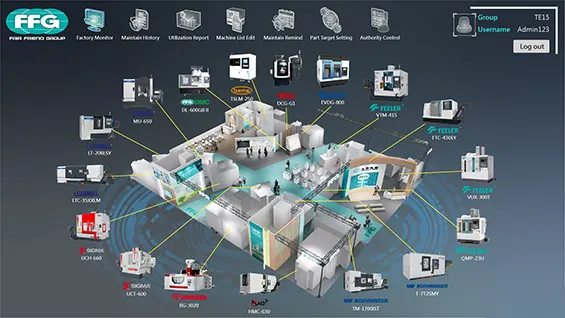

Through virtual-real integration, full-factory monitoring, and AI analysis, FEELER provides solutions spanning from the production line to management systems, creating a fully visible and predictable digital factory.

FEELER has applied smart manufacturing solutions across various industries, implementing automated production lines that demonstrate multi-process integration and practical intelligent production capabilities.

• 2D/3D AI vision technology

• Robotic arms coordinated with online measurement systems

• Remote monitoring and real-time feedback

• Virtual reality simulation for line efficiency and scheduling

• Continuous 24/7 production

• Integration of machines, cleaning, measurement, and AGVs

• Automated loading/unloading, tool changing, and full process tracking

• Virtual reality production framework for process monitoring

• Cloud-based order transmission and automated assignment

• Small-batch, multi-variety production

• Full-process monitoring to improve efficiency

• Flexible and transparent production workflow

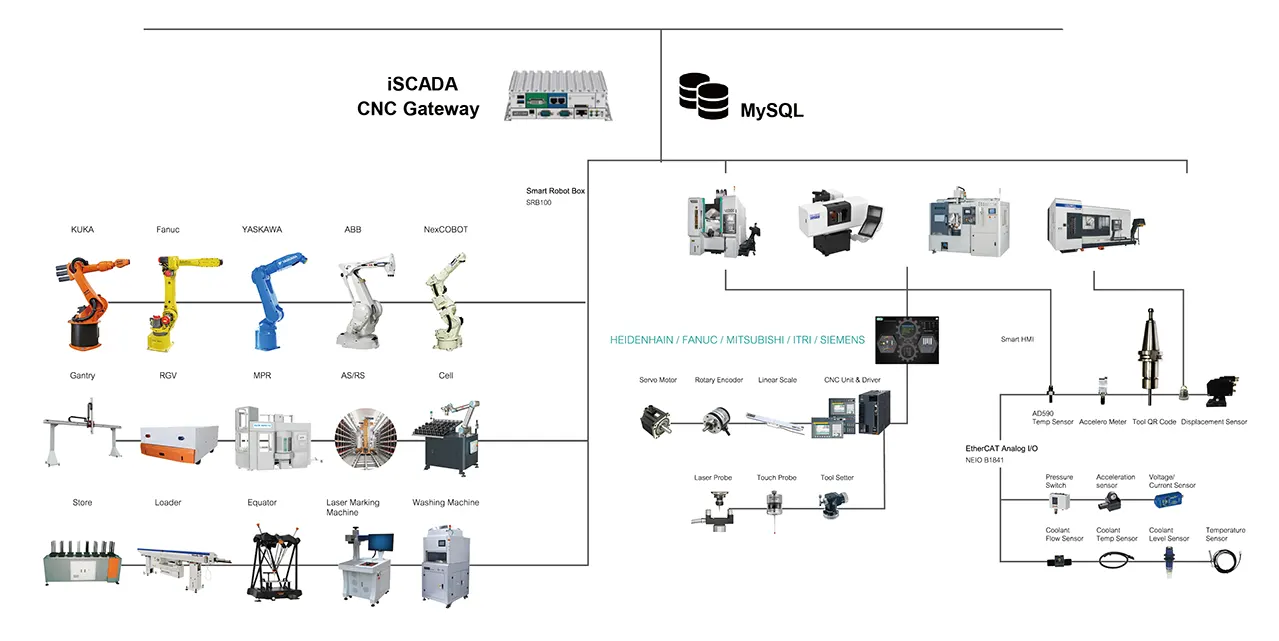

By linking CNC controllers (Fanuc, Mitsubishi, Heidenhain, Siemens, etc.) through the CNC Gateway, machine data is consolidated into the iSCADA and database platforms, forming the data foundation of a smart factory. This enables factories to evolve from traditional management to a transparent, measurable, and optimizable production model.

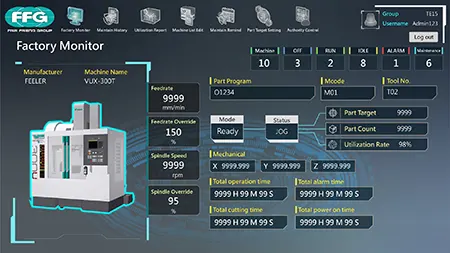

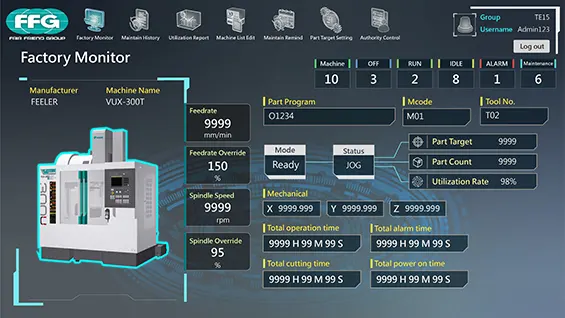

Real-time display of machine status, operating load, and abnormality alerts.

Immediate visibility of spindle, feed, and cutting parameters.

Statistics on machine utilization, daily output, work hours, and efficiency metrics.

Preventive maintenance reminders, maintenance schedules, and equipment health records.

The AI-Enabled Operations Command Center integrates plant production, equipment, and energy data, visualizing machine status, production progress, capacity, and energy consumption. AI analytics support precise operational decisions, predictive maintenance, and process optimization, enabling managers to efficiently monitor and improve performance across all stages.